Description

Function

-

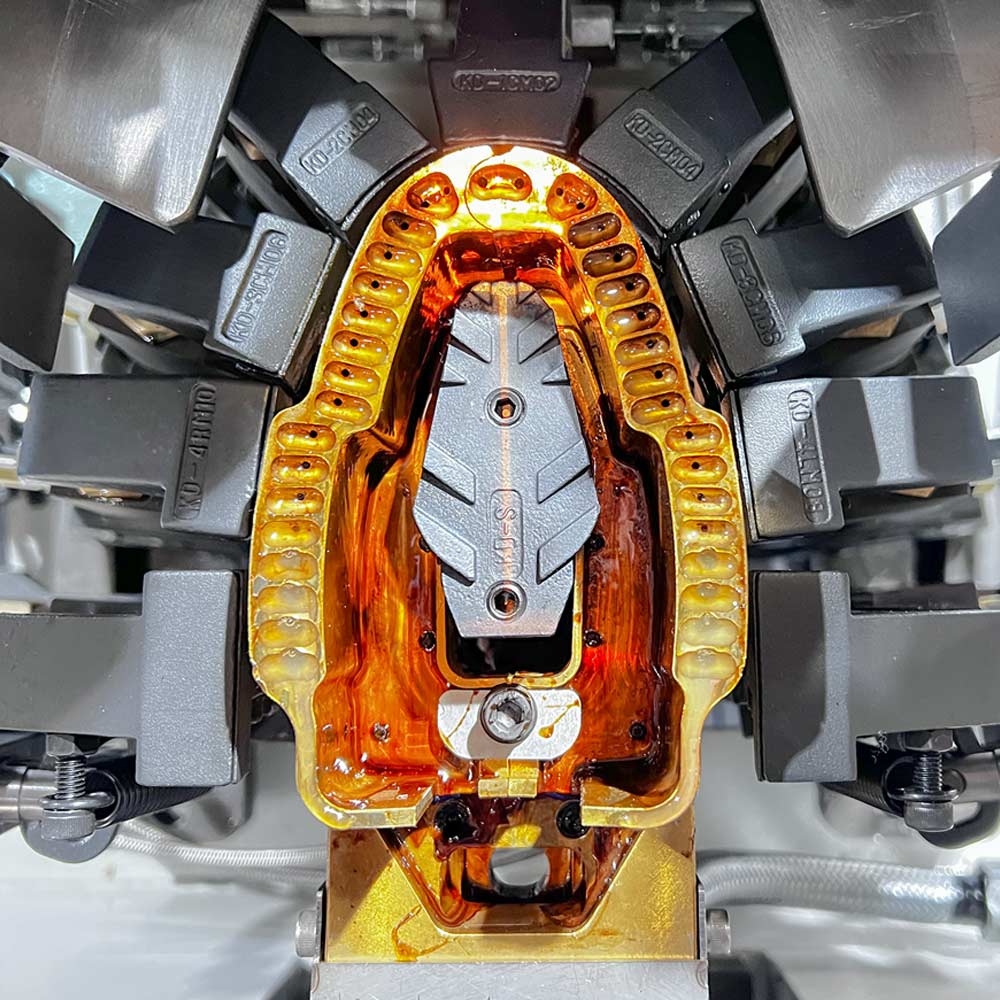

It is to pinch and pull the upper margin, then fold and bond onto the bottom of the shoe by continuously melting and feeding a rod-type hot melt.

-

Thanks to hydraulic 9 pincers and automatic thermoplastic injection, it is suitable for production of any size and kind of shoe: from the smallest children’s sizes to the largest men’s sizes, and for all type of ladies shoes with the required height of heel.

-

The machine also includes various kinds of hydraulic devices such as movable wiper elements, head sliding assembly, last supporter, heel supporter and toe band allowing to accomplish an effective toe lasting job.

-

KD-95A is designed for forming and lasting leather, PU, Nylon and Canvas shoes.

Advantages

-

The 9 pincers adjustment facilitates the operator in the effective lasting of unusual upper patterns or easy-to-tear materials.

-

Speed and precision on the pressure control and easy maintenance reduce the operating costs.

-

This model is equipped with a wide range of standard features such as a new center alignment lamp, a movable pincers system and a single pincers opening device for the production of various shoe designs.